HD series

HD Hypoid Gear Rotary Stage

High-precision positioning

A hypoid is a type of spiral bevel gear whose axis does not intersect with the axis of the meshing gear and the shape is a revolved hyperboloid instead of conical shape. The hypoid gear places the pinion off-axis to the ring gear or crown wheel. This allows the pinion to be larger in diameter and provide more contact area. The multiple contacts of hypoid gearing, with proper lubrication, can be nearly silent, as well. Therefore, they are stronger, operate more quietly, can be used for higher reduction ratios and can transmit higher torque. A higher hypoid offset allows the gear to transmit higher torque.Feature

IP-65 rated

IP-65 rated HD series is “dust tight” and protected against water projected from a nozzle.

High precision

The backlash is very low because of the JIS class 0 gear with ≦0.002mm geometric tolerance.

High stiffness & High torque CW/CCW,PUL/DIR

HD series is suitable for the cases when inertia is high or high torque is required due to its strong structure made of alloy steel.

High mechanical efficiency

Generally, hypoid gears have some sliding action along the teeth, which may reduce mechanical efficiency. However, the efficiency of HD series is up to 96%.

Lower noise

The noise of HD series under motor run-up condition at 1500rpm speed is lower than 50dB.

Long lifetime

Lifespan is increased because of the built-in gears made of high hardness & high density material.

High accuracy & High stiffness

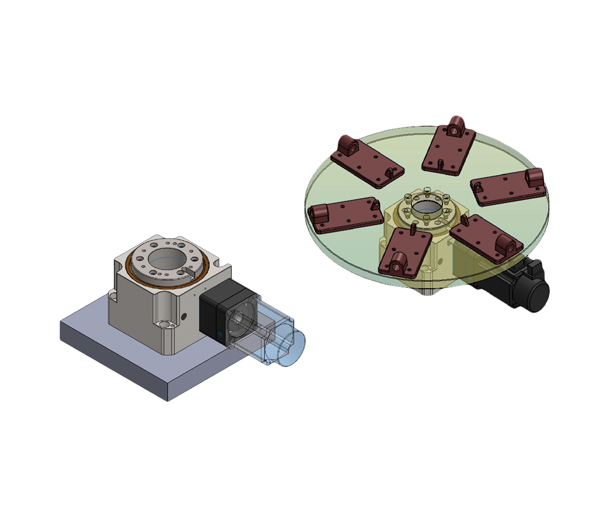

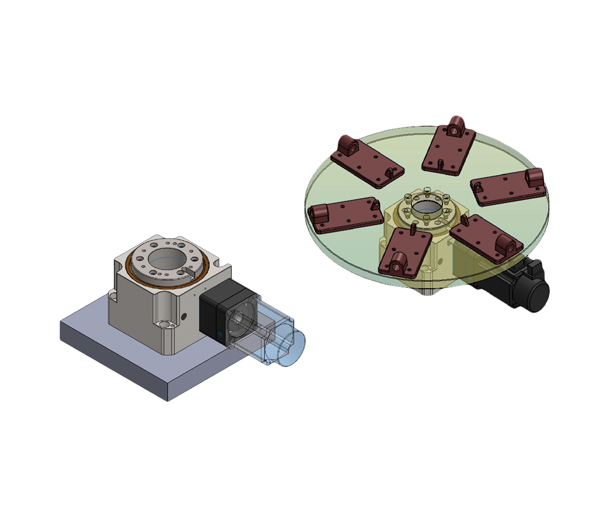

- Horizontal mounting

It’s suitable for the applications which high-speed positioning with a large size rotary table / a high inertia is required.

- Horizontal mounting

HD series can be also used for various applications afterbeing mounted with a XY stage.

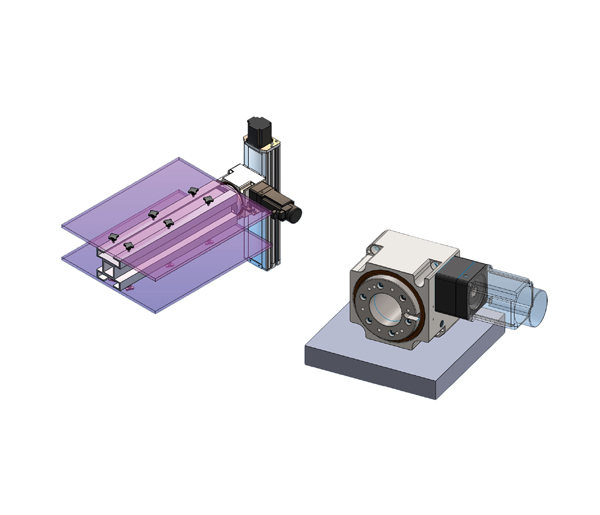

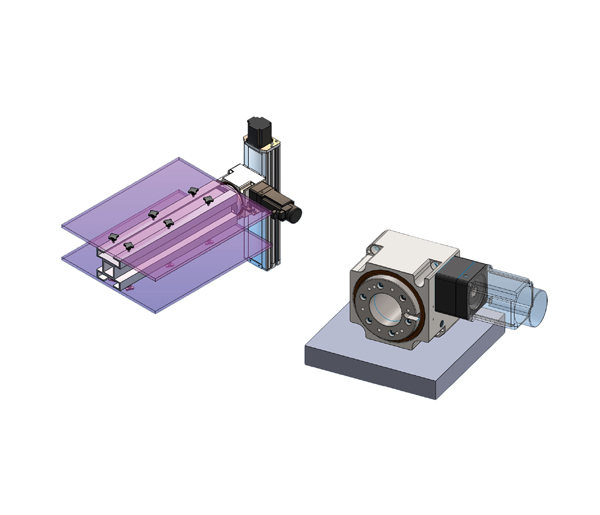

- Vertical mounting

For the applications such as rotating or moving vertically.

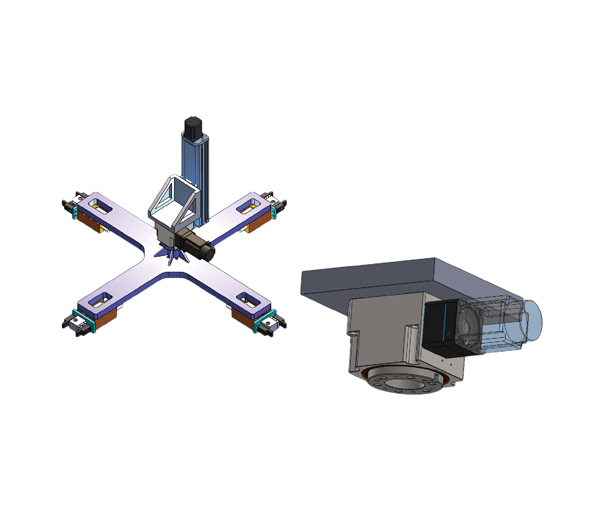

- Upside-down mounting

Users are able to use HD series with upside down mounting under a high load circumstance due to its high-stiffness structure.

HD150-30-口

HD200-30-口

HD Hypoid Gear Rotary Stage

High-precision positioning

A hypoid is a type of spiral bevel gear whose axis does not intersect with the axis of the meshing gear and the shape is a revolved hyperboloid instead of conical shape. The hypoid gear places the pinion off-axis to the ring gear or crown wheel. This allows the pinion to be larger in diameter and provide more contact area. The multiple contacts of hypoid gearing, with proper lubrication, can be nearly silent, as well. Therefore, they are stronger, operate more quietly, can be used for higher reduction ratios and can transmit higher torque. A higher hypoid offset allows the gear to transmit higher torque.Feature

IP-65 rated

IP-65 rated HD series is “dust tight” and protected against water projected from a nozzle.

High precision

The backlash is very low because of the JIS class 0 gear with ≦0.002mm geometric tolerance.

High stiffness & High torque CW/CCW,PUL/DIR

HD series is suitable for the cases when inertia is high or high torque is required due to its strong structure made of alloy steel.

High mechanical efficiency

Generally, hypoid gears have some sliding action along the teeth, which may reduce mechanical efficiency. However, the efficiency of HD series is up to 96%.

Lower noise

The noise of HD series under motor run-up condition at 1500rpm speed is lower than 50dB.

Long lifetime

Lifespan is increased because of the built-in gears made of high hardness & high density material.

High accuracy & High stiffness

- Horizontal mounting

It’s suitable for the applications which high-speed positioning with a large size rotary table / a high inertia is required.

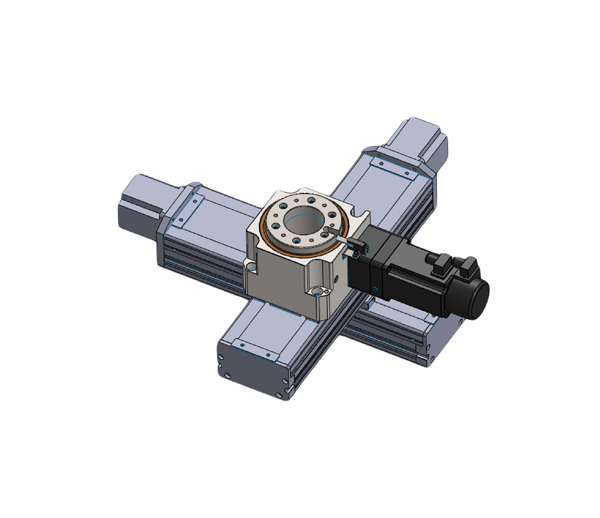

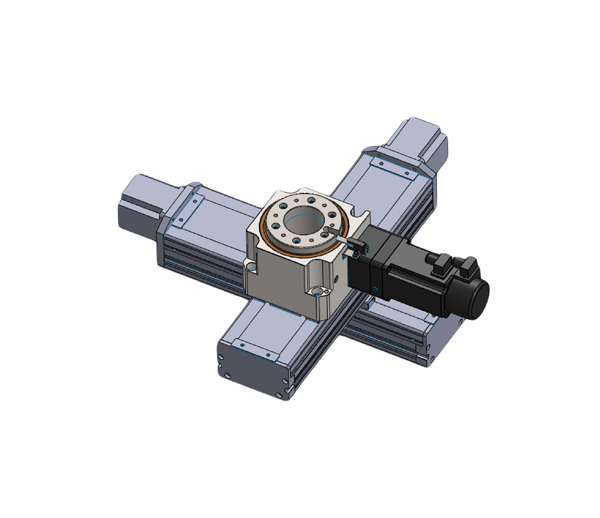

- Horizontal mounting

HD series can be also used for various applications afterbeing mounted with a XY stage.

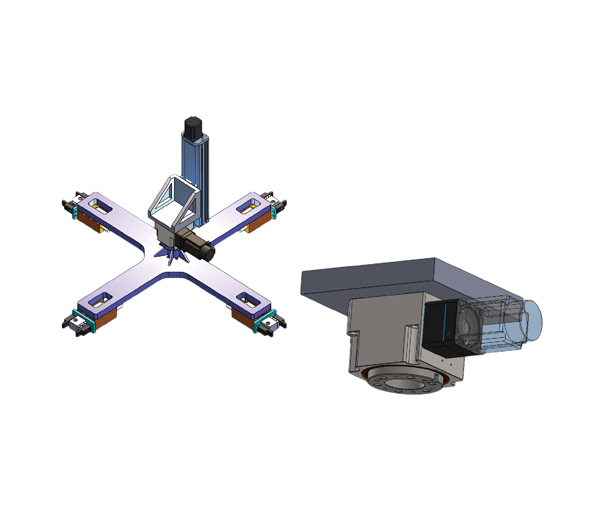

- Vertical mounting

For the applications such as rotating or moving vertically.

- Upside-down mounting

Users are able to use HD series with upside down mounting under a high load circumstance due to its high-stiffness structure.

HD150-30-口

HD200-30-口